Because there are so many different varieties of knives, customers often ask which ones are essential for the home cook.

Although there are many specialty pieces, one’s first two investments should be a chef’s knife and a paring knife. After that, you can begin adding knives such as a utility (slicing) knife, bread knife, boning knife, cleaver and any other specialty knife designed for a specific type of preparation.

If you’re interested in having a chef knife, our chef knife reviews and buying guide will help you get started. However, this article is aimed at helping you know what type of kitchen knives there are, and how to know which one is right for you.

Other than the chef holding it, a knife may be the most important tool in your kitchen. Knives are used for so many critical tasks that owning a substandard set of them can create a world of frustration. But how many knives do you need and how do you choose the ones that are right for you?

Most professional chefs consider their knives to be their most essential and personal tools. Since knives can be equally important for the home cook, Broadway Panhandler suggests considering the following factors when selecting knives:

Forged vs Stamped

Forging and stamping are the two major knife manufacturing processes.

- Stamped knives are generally stamped several at a time from sheets of steel. The blade of a stamped knife is fitted into its handle and is not considered one fluid piece of equipment. They are usually thinner, lighter and lack the balance of forged knives; therefore, requiring a firmer grip and more pressure when chopping, mincing, etc.

- Forged knives are individually made and the handle is riveted or molded around the tang. Their increased durability and balance compared to a stamped knife offset the higher required investment.

Blades of forged knives are produced when steel is heated to a very high temperature, set into a die and hammered to form the blade. The metal is hardened after being exposed to an extremely high temperature and then cooled by ice or in a chemical bath that contracts the steel and makes it dense.

This process produces a brittle blade, so another heating and cooling treatment, called tempering, relaxes the internal stress, making a more flexible blade. Coarse to fine grindings then create the taper and give the desired amount of flexibility.

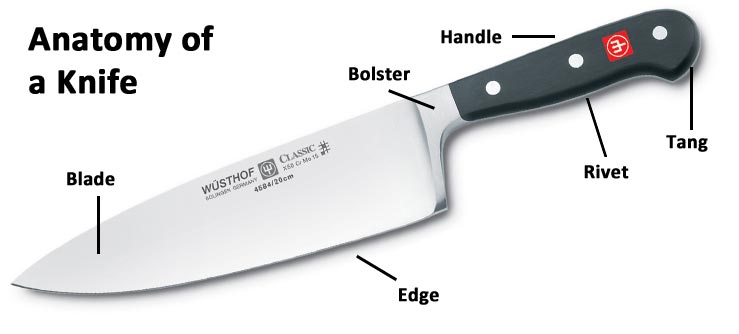

Finally, the knife is sharpened and honed to create the cutting edge. The greater attention given to developing a forged knife results in a heavier, front weighted blade that has a distinct bolster, a thick band of steel that lies against and perpendicular to the handle.

SEE ALSO: Differences between a Santoku vs Chef knife.

Six simple steps to choosing the right Kitchen knives every time

- Consider the type of knife you need. Kitchen knives come in many shapes and sizes. Consider your cooking style and habits. A good basic kit for an average domestic kitchen might include: A utility knife, a chef’s knife for chopping, dicing, mincing, and cutting, a paring knife for peeling, cutting, and trimming small items, a bread knife (serrated), and a carving knife for getting thin and even slices of meat from roasts.

- Feel the knife’s weight. A lightweight knife is good for speed and precision. A heavier knife is better for harder ingredients.

- Examine the balance of the knife. Quality knives have very good balance with not too much weight either in the blade or the handle. A well-balanced knife makes any cutting action easier and will mean less strain on your arm.

- Look at the handle. It should be solid, easy to clean, and well joined. The handle is often made of wood, plastic, toughened resins, or another strong material.

- Consider the blade. This is where you decide on forged vs. stamped.

- Look at the width of the cutting edge. Also consider the thickness and smoothness of the blade. The cutting edge should run the full length from tip to the handle.

Cutlery Steel

Long before metallurgy and knife making reached the current technology where high-carbon stainless steel blades became standard, low carbon or carbon steel blades were the best and sharpest available. Low carbon steel blades flourished for over 3000 years before stainless steel elements were added to the metal recipe.

Carbon Steel Blades

Carbon knives use metals that primarily contain iron, carbon and silicon with trace elements of tungsten, titanium, copper, manganese and others. Using a low proportion of carbon allows low carbon steel kitchen knives to be softer and more resilient than other cutlery steel.

The edges of carbon steel knives can easily be made razor sharp and easily be re-sharpened when dulled.

Because the low carbon blade is relatively soft it can get dulled fairly easily. But if used and maintained properly it can keep its razor sharpness almost continuously as it can be so easily honed back to its original condition.

Low carbon steel cutlery requires regular and careful handling and maintenance. If left wet, carbon steel cutlery will rust and corrode. After each use, the knife should be rinsed and dried immediately.

Darkening and discoloration is a normal reaction to the acidity of certain foods and will not degrade the blades performance. Keep a thin coat of mineral oil on the blade if not in use for an extended period of time.

Stainless Steel Blades

Following WWII, cutlery manufacturers started to experiment with stainless steel blades in order to eliminate the rust and discoloration issues associated with carbon steel knives.

Stainless steel elements include iron, carbon and silicon with the addition of chromium, nickel, molybdenum, vanadium and a host of trace metals. What they found was that the stainless-steel metal could not be easily sharpened and was a poor choice for fine quality professional cutlery.

It seems that the addition of nickel to the recipe degraded the benefits of carbon, which allows for edge retention and re-sharpening capabilities. Most stainless-steel knives in production today have serrated blades that do not require sharpening (i.e. Ginsu and Chef Tony).

High Carbon “Stainless” Steel Blades

By eliminating nickel from the stainless-steel recipe and increasing the proportions of carbon, chromium, vanadium and molybdenum, the currently available cutlery steel is known as high-carbon “stainless” steel.

This steel has high corrosion resistant qualities and the potential to have blades that can hold razor sharp edges for an extended period (compared to low-carbon steel) and be re-sharpened easily.

Cutlery steel continues to evolve with new technology and enhanced sharpening techniques. The search for an even better blade continues as new trace elements are added, proportions are revised and the tempering process adjusted.

The Knife Handle

Handles are typically made from hardwood, polypropylene plastic composition, or a combination of wood with infused resins. Composition handles can be molded into an ergonomically designed grip and wooden handles can be equally well shaped.

When considering a specific knife, pay close attention to how the handle is fitted to the blade. This is one of the few areas in which you can really see the craftsmanship and hand finishing. It is the defining factor of a high-quality knife.

The handle should be securely attached to the blade, should provide a secure grip and should not slip when in use. Be sure that there are no separations between the handle, the tang and the rivets. Crevices are very hard to keep clean and may harbor bacteria.

A la carte or a set?

One other thing you may want to consider is whether to get your knives one at a time or to purchase them in a matched set. There are benefits to both ways, so the decision is yours. However, if you want to buy them in sets there are a couple of different ways, they are available.

- In a block: Knives in a wooden block look great on (or under) the counter in your kitchen. Knife sets are available in several sizes: 5-piece, 7-piece, 10-piece, 12-piece, 23-piece, up to 36-piece. Already have the knives? You can find empty blocks to store them in.

- Rolled sets: Knife rolls are often used by professional chefs who value their knives so much that they carry the roll with them. For home chefs, a space-saving nylon knife roll securely stores your knives for easy transport to cooking classes, outdoor cookouts, and vacation homes.

- Magnetic knife holders: This option gets your knives off of the counter and can be a real space saver for smaller kitchens. Magnetic holders come with or without knives. Just be sure you install them so the kids can’t accidentally knock them down or get a hold of them.